Title: Hot Box Analysis

Client: SES

Software used: Ansys Mechanical

Duration: 4 Months

Keywords: ASME, BPVC, hotbox, axisymmetric, reactor, temperature, Y – Junction, load combinations, stress limits, conduction, convection, radiation

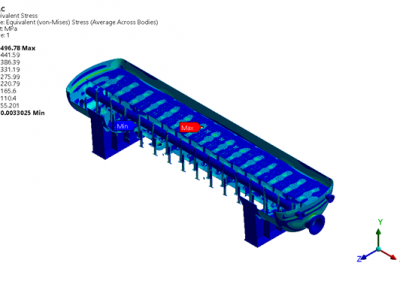

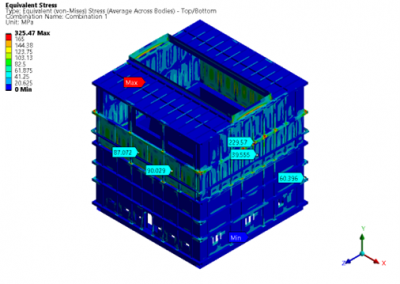

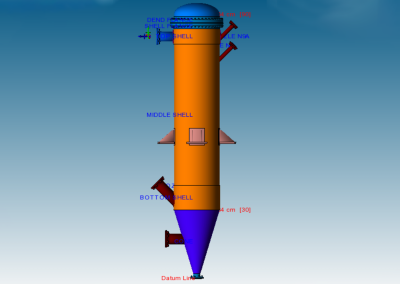

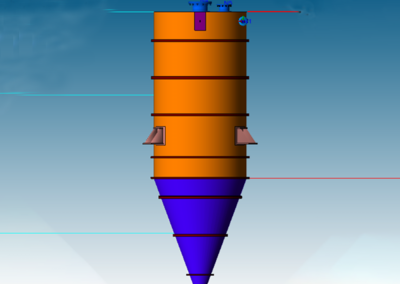

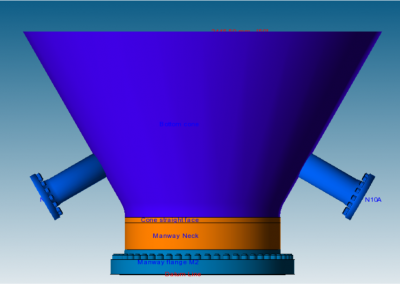

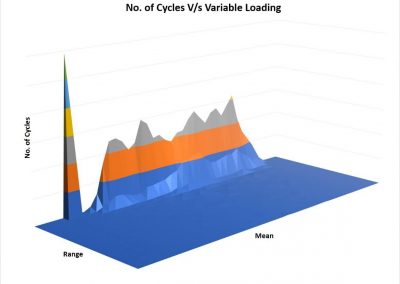

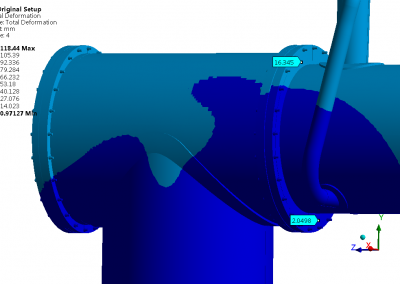

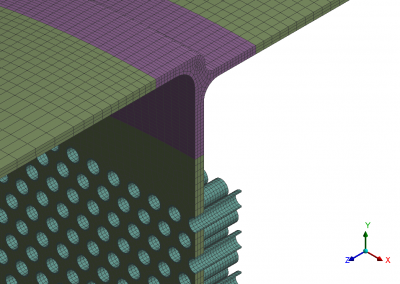

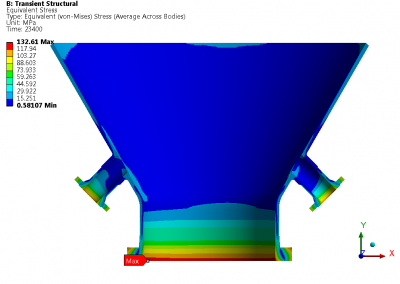

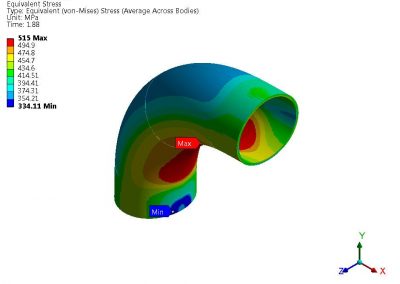

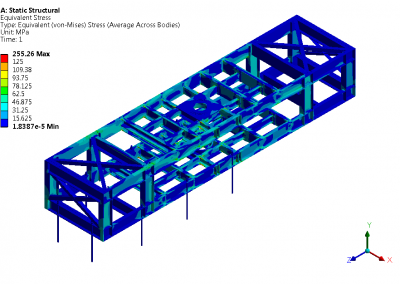

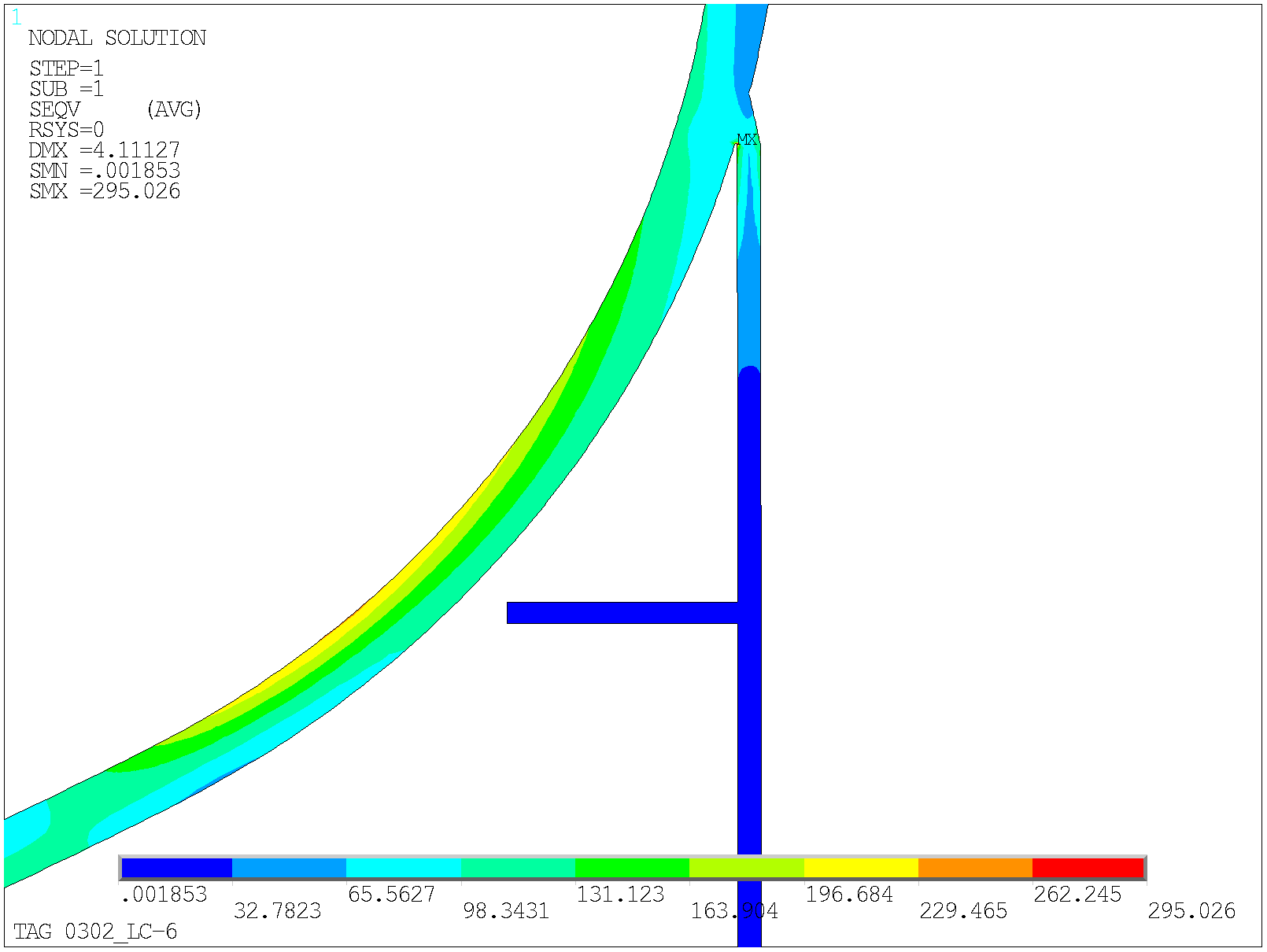

FE analysis of hot box for a series of reactors, viz. Low-temperature shift reactor, high-temperature shift reactor, hydrogenation reactor desulfurization reactor and deep desulfurization reactor are performed in 2D - axisymmetric model. The accurate prediction of the temperature distribution in the Y junction is critical as a small variation in the temperature results in a significant change in the stress values. The temperature distribution is obtained with boundary conditions of temperature on the inner surface, convective heat transfer coefficient on the insulation exposed to the atmosphere and radiative heat transfer within the walls of the hot box. For the obtained temperature gradient, static structural analysis is performed to evaluate stresses. Along with temperature, the other loads considered are design and operating pressure, dead weight, seismic and wind. Axisymmetric harmonic elements are used to apply non-axisymmetric load due to seismic and wind. The analysis is performed for these load cases, and the load combinations and qualification is performed as per ASME BPVC Section VIII Div. 2 Part 5. The stress assessment and allowable stresses for respective design and operating load combinations are as per the updated guidelines of the ASME 2019 edition.

Benchmark: FE analysis of hot box for a series of reactors, viz. Low-temperature shift reactor, high-temperature shift reactor,

Recent Projects