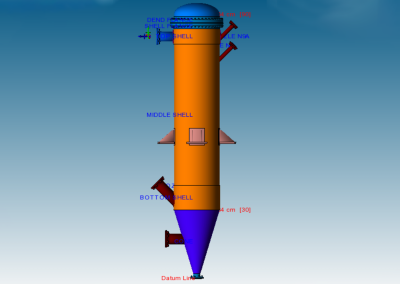

Title: Coke drum

Client: IDESA, Spain

Software used: PV Elite / AutoCAD

Duration: 4 Months

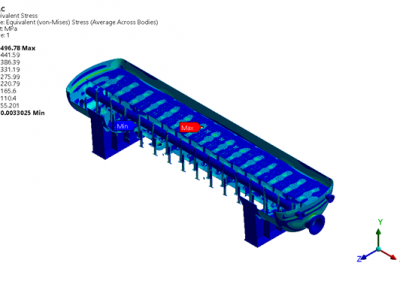

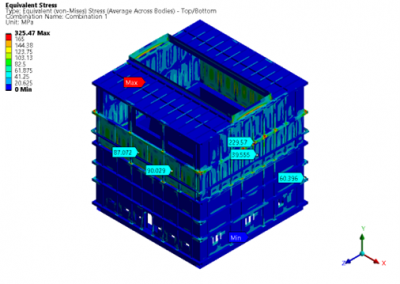

Keywords: Coke drum, PV-ELITE, FEA, Critical Requirement Sheet, ASME BTH-1, ASME SEC VIII DIV 1, ASME SEC VIII Div 2, cyclic loading, fatigue, WRC 107

Scope:

1) Requisition for Purchase plate and forgings

2) Critical Requirement Sheet (CRS)

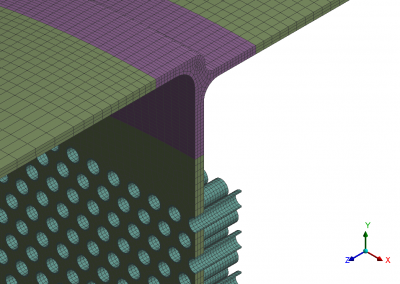

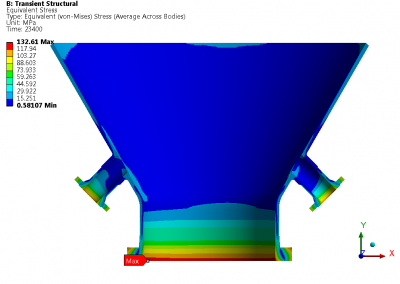

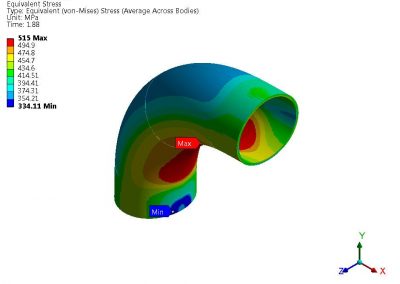

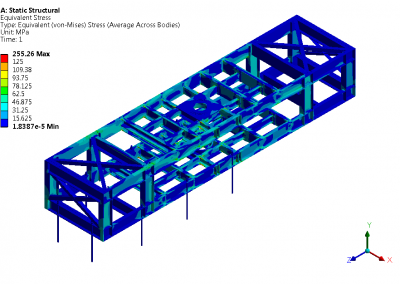

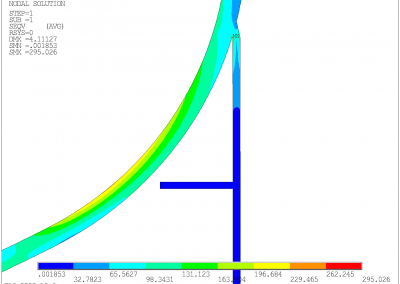

3) Calculation: per Code + FEA analysis

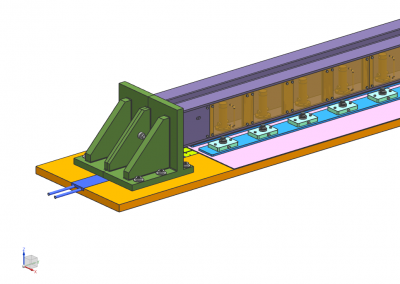

4) Handling arrangement design

General arrangement drawing, nozzle details drawing, nameplate drawing and hydraulic test drawing

Updating documents up to Client approval, including the submission of Comment Resolution Sheet

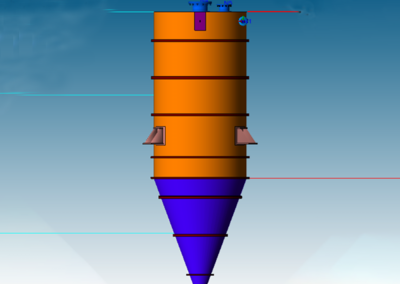

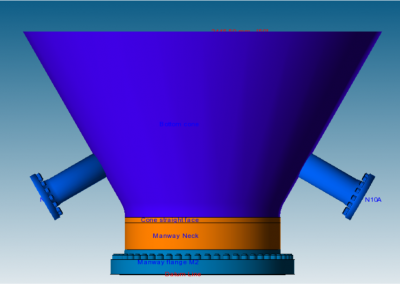

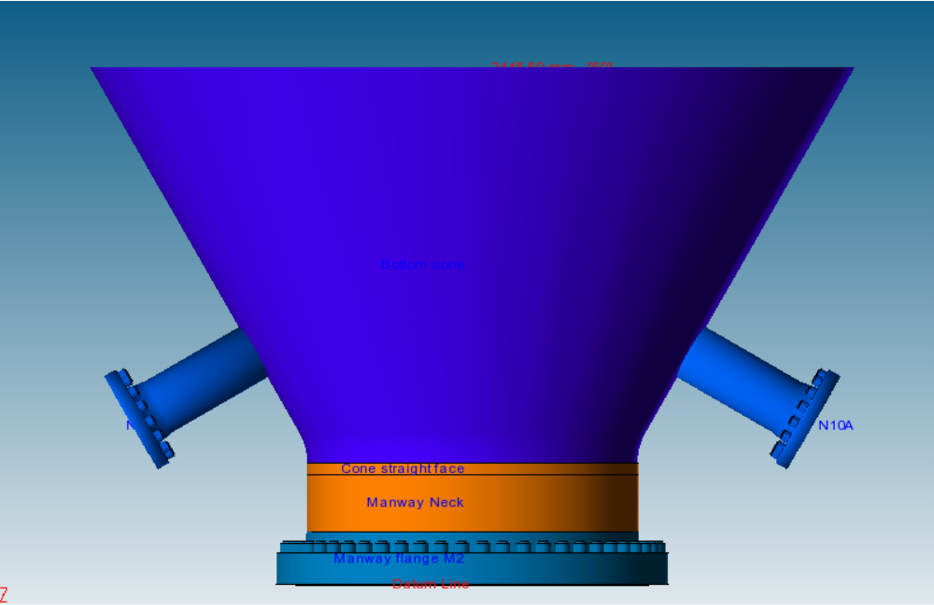

As part of the MIDOR expansion project, the bottom part of the coke drum cone was cut @2450 mm and replaced with the proposed design. The proposed design was validated using ASME BPVC Section VIII Div. 1. The nozzle configuration is checked for ASME BPVC Section VIII Div.2 Part 5 requirements.

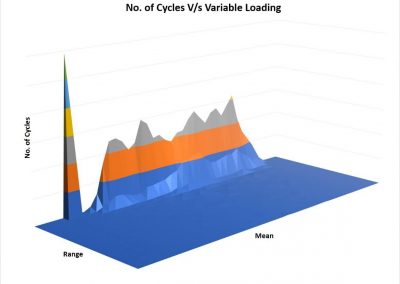

As the cone was subjected to thermal and pressure cyclic loading during service life, fatigue was applicable for the design. To ensure protection against cyclic failure, a detailed fatigue calculation was performed.

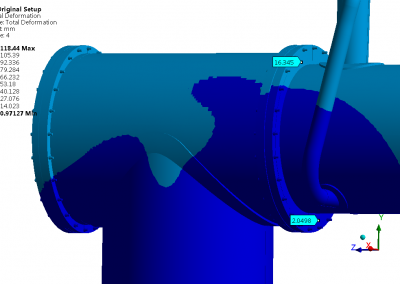

Nozzles were subjected to an external load, as this configuration is not covered by WRC 107 (537) /297, FEA was performed.

Lifting lug calculation was performed as per ASME BTH-1.

Benchmark: The project was U stamp, and the mechanical design report was approved without any hassle.

Detail fabrication drawing was prepared to cover all the aspects of manufacturing with tolerance on critical dimensions required as code and assembly.

Recent Projects